LONGWAY Services

Our Services

Our ServicesTesting

Industrial oil

Provide testing and analysis of various industrial oils such as used engine oil, grease, electrical insulation oil, organic heat carriers, turbine oil, gear oil, hydraulic oil, etc.

Modern equipment lubrication has become the core content of enterprise equipment management. According to nearly 25 years of worldwide research surveys show that.

- 70-85% of the hydraulic system failures and failures are related to the hydraulic oil, especially with the hydraulic oil contamination;

- 60-70% of the gearbox life shortening and frequent failures and lubrication effect is directly related to, for example, the use of unsuitable oil, not timely replacement and overuse, lubricant contamination and lack of lubrication, and so on;

- Research by SKF, the world's largest rolling bearing manufacturer, concluded that the main cause of bearing replacement comes from lubrication. The most effective means of extending bearing life is to keep the lubricant (grease) clean (dry is free of water, clean is free of dust);

It is no exaggeration to say that the lubricant is the blood of the machinery and equipment, and the life and longevity of the machine is in the lubricant. Equipment lubrication and oil monitoring has been seen by advanced foreign countries and the world's top 500 as an important measure to improve productivity and reduce maintenance costs, is to grasp the important value of the opportunity in the hands of business managers.

Hengrun commodity inspection industrial oil monitoring center introduction:

Hengrun Commodity Inspection Co., Ltd. in Changshu test base construction of 2,300 square meters of industrial oil monitoring and testing center, with a dedicated lubricant testing center equipment investment of 15 million, more than 100 sets of large and important equipment.

Why choose Hengrun's lubricant testing service:

(1) Competitive price - professional to create efficient, the laboratory in the operation of the most advanced automated testing technology, and with the help of scientific process management, to achieve high efficiency in the production of laboratory data and low waste of resources, so as to provide customers with a fair price;

(2) accurate test results - the laboratory has a mature quality system, and designed a perfect quality control means to ensure that the test meets the requirements of the test method repeatability and reproducibility, so that you can rest assured that based on the test report on the state of operation of the equipment to do optimization;

(3) help customers solve problems - more focused on helping customers solve practical problems, according to customer demand for research and development of targeted testing methods, urgent customer urgency, so that some of your non-routine problems are properly resolved;

(4) high timeliness - more urgent samples, routine items can be the same day results, normal report 3 ~ 5 days out of the results - to ensure that the first time to guide the operation of the equipment;

(5) data archiving and analysis - if you do a full set of lubricant monitoring project in Henglun for a long time, through Henglun Laboratory Information Management System ChemistryLIMS to provide the appropriate data summary and analysis services, so that you have a clear understanding of the level of lubrication management of the equipment to improve the efficiency of the equipment management.

Advantages of the report:

1. The report is scientific and contains the following contents:

■ Lubricant physical and chemical performance status

■ Equipment wear metal status

■ The entry of external pollutants

■ Coolant leakage

■ Lubricant additive changes

2. Accurate trend analysis chart: Based on the continuous analysis data, trend analysis chart is made for each piece of equipment, which is helpful for equipment supervisors to understand the trend of equipment wear and lubricant deterioration, and to guide the predictive maintenance and oil change preparation.

3. Warning signs: red, yellow, green as a warning color, intuitively indicate the state of equipment and lubricants, so that people who do not understand the analysis data can also use the report.

Part of the test item notes:

1. Viscosity@400C, 400C

Selection of the appropriate viscosity is the first issue in the correct selection of gear oils and hydraulic fluids. Lubricants with too low a viscosity do not easily form an oil film and accelerate wear. On the other hand, a lubricant with too high a viscosity will increase the internal friction, which will increase the power consumption. Too high viscosity will also cause the equipment in the early start-up difficult to pump the oil to the lubrication part in time, resulting in wear.

2. Water content

The presence of water affects the lubricant to form a continuous oil film, so that the lubrication effect becomes worse. Will not only accelerate the corrosive effect of organic acids on metals, and cause the hydrolysis of metal salt additives, additive failure and precipitation, and even lead to oil blockage.

3.TAN Total Acid Value

After long-term use of lubricating oil, and the oxygen in the air chemical reaction will produce organic acids, with the extension of the use of time, the acid value of the increasing, causing the deterioration of lubricating oil, which leads to the corrosion of machinery and equipment.

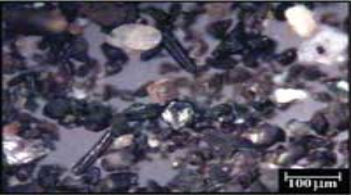

4. Cleanliness

External pollutants into the equipment and the working process of the various particles will lead to pollution and deterioration of the lubricant, thereby accelerating the friction of the parts of the surface of the wear and tear, so that the performance of the equipment to reduce the operation of the shortened life.

5. Metals Elemental Scanning (ICP)

Emission spectroscopy is a valuable technique for lubricant analysis and machine wear condition monitoring. It is the only lubricant monitoring technique that simultaneously provides the concentration of wear metals, the concentration and type of solid and fluid contaminants, and the presence and content of inorganic metal salt additives.

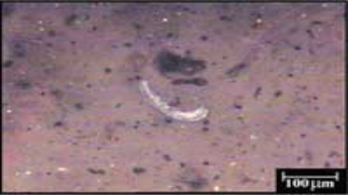

6. Analytical Ferrography

Analytical Ferrography monitors the wear state of wear particles within the lubricant, providing a clear understanding of the bearing's operating condition and wear trend, which in turn identifies wear areas and allows for early adoption of reasonable maintenance measures.

Severe sliding wear |

Fatigue wear |

Cutting Wear |

Sealing materials, fibers, etc. |

Contact us:

Manager Yang

E-mail: tinting.yang@longwaysh.com

Manager Liu

E-mail: aaron.liu@longwaysh.com